Special Ed's HV-Maxx Project

Last year Special Ed purchased a used Pro .15 T-Maxx after Dageek bought one and got his juices flowing. The thing needed all kinds of work. About the only thing Ed didn't have to replace to get it running was the tranny (but that had its own issues as well...won't shift into 2nd). Anyhoo...there came a point where he had just had enough of the damn thing and decided to get rid of it. Ed had to find some poor sucker to take it off his hands. So...he sold it to Dageek. You'll see that T-Maxx on this site...his name is Ripper.

The only problem with getting rid of Ripper is that Ed still had the RC Monster Truck jones. He knew, however, that he didn't want to get another nitro-powered vehicle. He did want the speed though. So Ed set out to find a way to have a fast electric truck. That's when he learned about brushless motors. Long story, short, Ed bought an E-Maxx and is in the process of turning it into a brushless-powered monster. He's starting with an HV-Maxx system. Even though it's not the fastest he can get, he thinks it will be plenty fast enough for his purposes. In any case, it will be faster than the stock E-Maxx which is exactly what he's after.

This page will sort of document the E-Maxx's transformation from stock to brushless. Ed didn't take pics of the truck when it was completely stock...because he just decided to document this process. So for what it's worth (not a whole friggin' lot), here's the story of how Stitch goes from stock to brushless (with other upgrades).

|

Ed upgraded the shocks to the Proline Powerstroke kit. At the time he took this pic he had only done the rears. Note to self...remember to ensure the center shaft is connected BEFORE you attach the rear assembly to the chassis :-) At the same time he upgraded the shocks Ed replaced the stock CVDs with MIP steel CVDs (necessary for the added power of a brushless motor). |

|

He also bought a set of Imex Dirt Dawg tires as he prefers a tread pattern that will work well on both dirt and street. Ed thought these were a good compromise. Along with the new tires he bought new wheels. The wheels he chose were Maximizer Products' standard composite beadlocks with the five hole design. We think they look pretty bad-ass. Ed was also tired of baking wheels to break down the glue. The beadlock wheels give him the ability to take them off and put new tires on without having to fight the glue. Putting them together wasn't exactly easy but after he figured out a good system on the first wheel, the last three were a snap. |

|

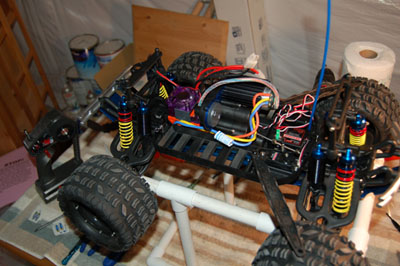

Here's Stitch with the stock body after the new wheels, tires and shocks. Ed is not especially fond of this green color but that's the way it came so he'll deal with it until he bashes it out of existence. |

|

Here's Stitch with both of the bodies Ed currently has. You can see that he hasn't yet put the new motor on. He does have it but is waiting for a few more parts. |

|

The underside of Stitch showing the new aluminum chassis braces and skid plates. |

|

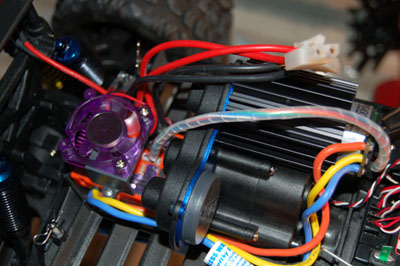

The new motor is now installed. It was easier than Ed expected. The HV-Maxx drops right in using the original holes. The hardest part was lining up the new pinion gear. He used a piece of paper to set the spacing and it worked like a champ. |

|

A closeup view of the new motor installed. It came with a plastic cap to cover the hole where the second motor went so that dust can't get in. The holes in the cap weren't big enough to take the stock screw so Ed reamed a couple of them out and it went right on. |

|

As is mentioned at the beginning here, Ed replaced the stock CVDs and center drives

with the MIP steel ones. We are happy to say that the front and rear CVDs are holding

up just fine. HOWEVER, the center drives are another story. They are held on to the

tranny with a pin that is held in place by a grub screw (abbreviated version). That

damn pin decided it wasn't going to stay in place (something I understand to be a

common problem with this particular MIP product). Ed used the info he found on

MisbehavinRC's website to try and bulletproof the setup. He notched the pin before

tightening the grub screw against it and then covered both ends of the pin with

Shoe Goo. The pin still blew out. So he roughed up the bell where the pin goes

through on both sides and then soldered it in. The pin still blew out. Needless to

say Ed was thoroughly ticked off by this. The problem is that when the pin comes out

it doesn't just fall out because the shaft is spinning at such a high RPM. It comes

out gradually and eats a giant hole in the chassis!!!

Ed had a heck of a time finding replacement pins for this because MIP doesn't make a rebuild kit specifically for the center drive on an E-Maxx (if they do he didn't find it anyway). So Ed had to use pins for LST's, T-Maxxes and other trucks. None of them was an exact fit so it wasn't real easy putting it together. Anyhoo...after going through this several times (the pin blew out everytime I drove the truck), he decided he needed to find an alternative. That's when Ed found the E-Maxx Steel Dogbone Kit manufactured by Kershaw Designs. Rather than a dogbone on one end and a bell whatever setup on the other, the Kershaw Designs kit has dogbones on each end. The grub screws come already covered in thread lock which was a nice touch. The kit fit perfectly and went on with a lot less fuss than the MIP kit did. Ed has put several hours on the truck with the new bones in place and has yet to have a problem. Ed admits to being a little worried at first about how well the dogbones would sit in place and whether or not they would put too much pressure on the tranny. As it turned out, these fears were unfounded and never came true. Ed knows a lot of people swear by the MIP kit but he will never use them for his center drives again. Ed recommends you at least check out Kershaw Designs and see what they have to offer. He suspects it will be the best decision you make regarding setting up your brushless E-Maxx. And by the way...they do some pretty awesome custom work. Simply amazing!!! !!!UPDATE 11/28/06!!! What? That wasn't long-winded enough for ya? Well...we thought the brushless E-Maxx story was over but were wrong. For some reason the motor kept shutting down. It was thermalling. Nothing Ed tried resolved the problem. The batteries were even getting exceedingly hot on ten minute runs. This didn't happen with any of the other vehicles even when the motors and ESCs were hot. So Ed looked around and found info on a forum (can't recall which forum and didn't save the link) stating that the HV-Maxx 4400 has a tendency to get hot due to...and that's where his recollection stops. They said the new HV-Maxx systems resolved the problem. Ed therefore got himself a new HV-Maxx 4.5 from RC Boyz. Man does that thing rock. It's hands down faster than the 4400 and the motor, ESC and batteries no longer heat up like they used to. They don't sell the 4400 anymore so you don't have to worry about running up against the heat problem unless you buy one used. |

|

HOME